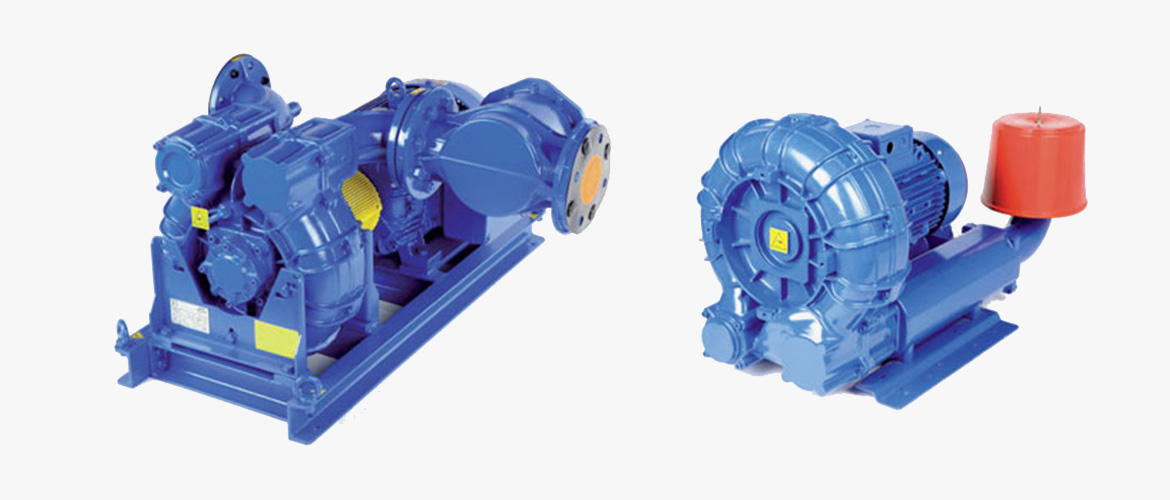

Rotary Wings

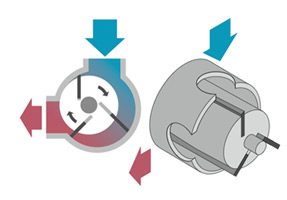

Working Principle

A rotary piston blower consists of a stator consisting of two symmetrically arranged, counter-rotating pistons in the form of three gears. The pistons rotate at a constant speed, performing the compression process.

The fluid to be transported enters the chamber formed between the stator and pistons and is conveyed to the compression outlet by the rotational movement. The final pressure level depends solely on the frictional resistance in the pipes and the operating conditions.

While maintaining a constant pressure, increasing the blower speed proportionally increases the fluid flow rate. The device automatically adjusts itself to the operating pressure, preventing unnecessary energy consumption.

ATEX Compliant Solutions

Our rotary piston equipment is certified in accordance with the ATEX 94/9/EC directive for use in areas where potentially explosive atmospheres may occur.

An explosive atmosphere is a mixture of gas, vapor, mist or dust mixed with air in certain proportions that can cause an explosion when in contact with extreme temperature, electric arc, spark or other ignition source.